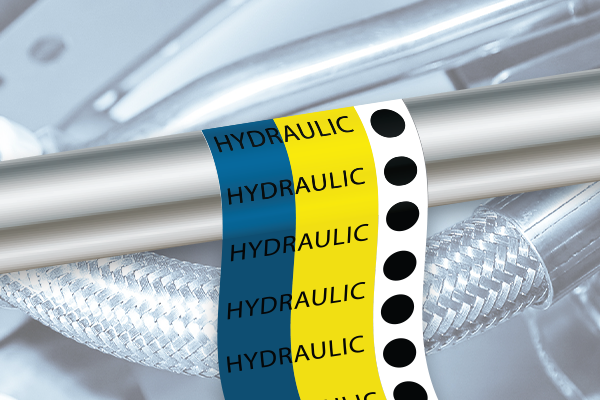

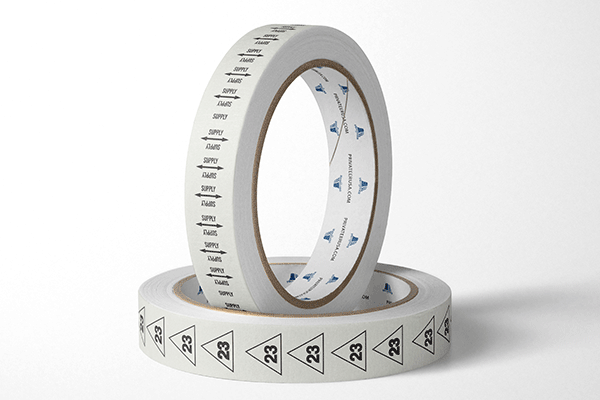

Fluid Line Identification Tape

Frequently Asked Questions

Aircraft Tubing Identification

Learn Why Privateer LTD. Is Uniquely Qualified To Serve The Aerospace And Military Industries

Privateer, Ltd. was established in 1972 to print vinyl identification marking tapes for the Navy. By 1980, we were producing Vinyl, Mylar, Imprintable, Glass Cloth and Fiberglass tapes for all branches of the U.S. Military, as well as Sikorsky, Boeing, Grumman, and Lockheed—to name a few. Our business expanded into nameplates and decals for the international aerospace industry and a myriad of labeling solutions for the private sector.

Search Below

Privateer is located an hour and a half from New York City, in Southern Connecticut on the Long Island Sound.

Our phone number is 860-526-1838.

Our website address is www.privateerusa.com

Please contact Sherri Schweitzer at 860-526-1838.

Privateer has been producing for the Aerospace Industry since 1972.

Privateer produces ID Marking Tapes for fluid lines, Decals, Stencils, Labels, and Nameplates for all your Aerospace needs.

We have been serving the Aerospace, Automotive, and Military sectors for almost 50 years.

We manufacture for companies including Boeing, Sikorsky, Lockheed, Bombardier, Gulfstream, NASA, etc. We have distributor relationships. We cater to the small tube benders and assemblers who appreciate the low minimums and quick turnarounds.

Privateer, Ltd. was established in 1972 to print vinyl identification marking tapes for the Navy. By 1980, we were producing Vinyl, Mylar, Imprintable, Glass Cloth and Fiberglass tapes for all branches of the U.S. Military, as well as Sikorsky, Boeing, Grumman, and Lockheed—to name a few. Our business expanded into nameplates and decals for the international aerospace industry and a myriad of labeling solutions for the private sector.

Military standards detail the processes and materials to be used to make the product.

An approved manufacturer has met rigorous testing, performance, quality, and customer satisfaction requirements.

Privateer has been ISO certified since 2018. Certificate number 56441.

ISO certification is a commitment to quality. Certification is an indicator that Privateer follows world class specifications and standards during its production process, leaving less room for error while fostering innovation, growth, and the ultimate goal of complete customer satisfaction.

Privateer, Ltd. does not currently manufacture or import any chemical substances on their own or in our product in quantities of 1 ton or more per year. Additionally, imported Privateer, Ltd. product does not contain substances intended to be released during the normal and reasonable foreseeable conditions of the products use as defined by the REACH regulation which negates a direct REACH obligation to pre-register substances. The use of substances of very high concern (SVHC) are not part of our manufacturing process. The RoHS (Restriction of Hazardous Substances) directive is an EU directive aimed at reducing the harmful environmental impact of waste electrical equipment by restricting the use of known dangerous substances. As of 1st July 2006, new electrical and electronic equipment introduced into the market and falling into certain product categories (with some exemptions) may no longer contain the following chemicals above specified maximum concentration levels: Lead Cadmium Mercury Hexavalent Chromium Polybrominated Biphenyls (PBB) Polybrominated Diphenylethers (PBDE) Standard Products. The labels supplied by Privateer, Ltd. are exempt from the requirements of this directive due to the simple fact that they do not require electricity to function.

Privateer tapes are a proprietary construction of materials that were developed, based on rigorous military performance standards, to withstand high temperatures, aggressive solvents and extreme environments.

Tube and pipe marking ensures that individuals working on an aircraft are aware of what pipes are carrying as well as any potential hazards associated with the pipe contents.

All tapes are individually bagged, marked inside core and on the bag with part number, po number, lot/job number, date of manufacture and date of expiration. These rolls are then securely packed in sturdy weight cardboard boxes and labeled for shipping. All certificates of compliance and other required paperwork is enclosed within the box or in clearly visible envelopes affixed to the outside, depending on requirements.

Our minimum order is one roll.

Skydrol™ is the trade name for a phosphate ester hydraulic fluid used on aircraft. Douglas developed it in the 1940’s, Monsanto in the USA manufactured it for years and more recently Eastman took the product into their portfolio. Skydrol is fire resistant and retains a low viscosity at the very low temperatures at altitudes of 10,000 meters and higher making it indispensable for aircraft.

Identification Tapes are installed at time of manufacture of new aircraft, in repair and rebuild stages of older aircraft. Tube assembly manufacturers also may apply the marking tape as part of their finished assemblies.

In general, each line shall be identified as to function and subsidiary functions when required, applicable hazard and direction of flow if applicable. Function tapes shall be placed on both ends of a line 24 inches and longer, as near to the end as practical. Only one identification group shall be required on these lines. Where tube bends and table support location prevent subfunction tape application, only a primary system function tape need be required. Identification within a group shall be a minimum of 1/32 inch apart. Tape is wrapped 1.5 times around diameter of tube.

The methods and instructions may be found in Mil-Std-1247 and may or may not be supplemented by specific end user requirements.

Providing your carrier number ensures you get the exact service you want, while also keeping your shipping costs to what you have negotiated, which could mean savings for you.

Our tapes are certified for 2 years.

Yes. We retain all records and paperwork for 10 years. These documents can be located and reviewed on our website under our CAPABILITIES tab.

We guarantee that what we ship to you will meet your purchase order requirements, will be built to applicable drawings and specifications, have 100% shelf life, and be free from defects. If your satisfaction to those points is not met we will replace the roll promptly at no charge.

First orders are typically by credit card, with subsequent orders on a Net 30 basis. Additional terms, such as 2% 10, or distributor agreements may be negotiated with a phone call.

Call our Operations Manager, Sherri Schweitzer, at 860-526-1838 x58.

Anything that isn’t a special order has a lead time of 10 business days. Expedites are handled on a case by case basis.

We supply nameplates with a slightly longer leadtime of about 3 weeks. Please supply drawing with your request for quote.

We supply stencils with a slightly longer leadtime of about 3 weeks. Please supply drawing with your request for quotes.

Aircraft Manufacturer Product Names for Identification, Marking Tapes used for their Aircraft Tubing, Hydraulic and Electrical Systems are typically preceded by a grouping of letters associated with the specific company. For best results, type the first one or two letters or any letter / number of the product you are searching for. As you type, results should populate the table for you to see.