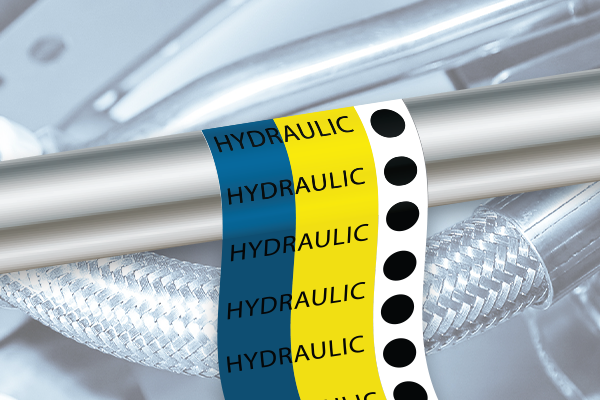

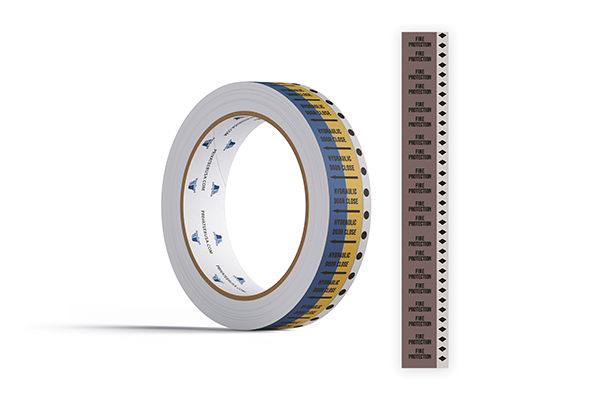

Aircraft Tubing Identification Tape

Privateer LLC is an original manufacturer of aircraft tubing identification tape. We offer the best pricing, a one-roll minimum order, and fast delivery!

- Privateer is a Manufacturer of FLI Tapes

- FLI Tapes Meet MIL-STD-1247 and MIL-T-9906

- Quality Mgmt. System Certified to ISO 9001:2015

- 10 Day or Less Turnaround Time

- One (1) Roll Minimum Order Quantity

- Easy Rapid Quoting / Ordering Process

- Personal Customer Service

- Domestic and International Shipping

Quick Overview

Manufacturing Tapes To Government Specifications Since 1972

Aircraft Tubing Identification Tape products, are also referred to as Fluid Line Identification Tapes (FLI). These tapes must meet or exceed the current revisions of the following Military and Commercial OEM Standards:

- MIL-STD-1247

- MIL-T-9906

- PPP-T-66E,

- FED-STD-595

- BPS-T-151

- MIL-I-19166

Privateer LLC is one of only few companies in the world that is qualified to manufacturer these types.

Materials of Construction

Privateer aircraft tubing identification tape products are comprised of the following materials. Polyester, Mylar, Vinyl, or Fiberglass. These materials are resistant to extreme weather conditions, harsh chemical environments, high heat, corrosive environments, and chemicals such as jet fuel and hydraulic liquids such as Skydrol™. We supply FLI tapes in rolls directly to end users, distributors and OEMs associated with the aerospace industry including precision tube benders, wire harness fabricators, and hydraulic system fabricators servicing the aircraft and military tube bending industries

Contact Us To Purchase Tapes Today

Since we have been manufacturing aircraft tubing identification tape since 1972, we are familiar with part numbers and other related information. Please send us an email or complete the form on any page. We respond quickly! We look forward to working directly with you! Thanks.

Privateer LLC is committed to the complete satisfaction of its customers. We exercise this responsibility through continual training of our employees, adherence to proven procedures and timely review of our quality system for suitability and effectiveness with a mindset for constant and never-ending improvement, and by our total commitment to meeting our customer requirements. Our objective is to deliver defect-free products, on time, every time.